Stable and simultaneous grinding of the workpiece end face is possible on the periphery of the grinding wheel.

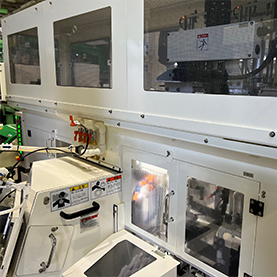

A high efficiency machine for grinding short diameter long workpieces

![]()

![]()

This Grinding Machine is equipped with a function that recognizes position information as its standard, so even individuals unfamiliar with the machine can use it with peace of mind.

Gantry loader

Parts feeder

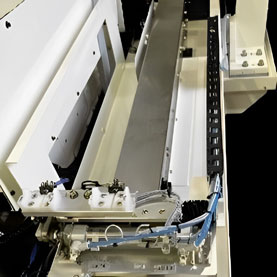

Conveyer

Conveyer belts

|

|

|

|

|

| Dimensions | φ10×L36 | φ3×φ2×L9 | φ47×L18 | φ6×L80 |

| Material | SCM20 | — | SCM20 | SCM435H |

| Roundness | 2.0 | 2.0 | 5.0 | 3.0 |

| Cylindricity(μm) | 3.0 | 4.0 | 5.0 | 3.0 |

| Surface roughness(μm) | Ra0.2 | Ry1.6 | Rz1.6 | Ry1.6 |

※The values are based on requirements.

*Please view the table by scrolling horizontally

The issue

The time it takes for Cylindrical Grinders cannot be shortened for small-diameter long workpieces.

The only method would be to increase production along with the increased number of equipment.

After implementation

By implementing our angular Centerless Grinder, they reduced the grinding time by 68%. One Centerless Grinder can now produce the equivalent of three Cylindrical Grinders.

| TO-5010S-AR1 | ||

|---|---|---|

| Grinding performance (single work) |

Grinding diameter | (Standard)φ3~40mm |

| Grinding diameter | (Large)φ30~100mm | |

| Diameter difference of workpiece | MAXφ40(Maximum gap 20mm) | |

| Grinding length | 100mm | |

| Range of manufacturing | Angular angle | 0~20°(fixed) |

| Center-height angle | 7°(fixed) | |

| RW angle | ±1.0°(fixed) | |

| Grinding wheel | Dimensions | φ510×100×φ228.6 |

| Minimum diameter | φ360 | |

| Motor capacity | 5.5kW | |

| Adjustment wheel | Dimensions | φ330×100×φ203.2 |

| Minimum diameter | φ280 | |

| Driving system | V belt | |

| Revolution per minute | 1~750rpm | |

| Motor capacity | 3.5kW(Servo motor) | |

| Machine dimensions | W2100×D1400×H2000 (Including control panel) |

|

| Machine weight | 3500kg | |

*Please view the table by scrolling horizontally

Standard specifications (standard attachment functions)

Optional (specialized attachments)